Site Links

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Quick Links

Categories

In this Discussion

Please review the site Rules, Terms of Service, and Privacy Policy at your convenience. Rules, TOS, Privacy

Get familiar with the reaction system: Introducing the Reaction System

Turn2, inventing new ways to ruin DIY

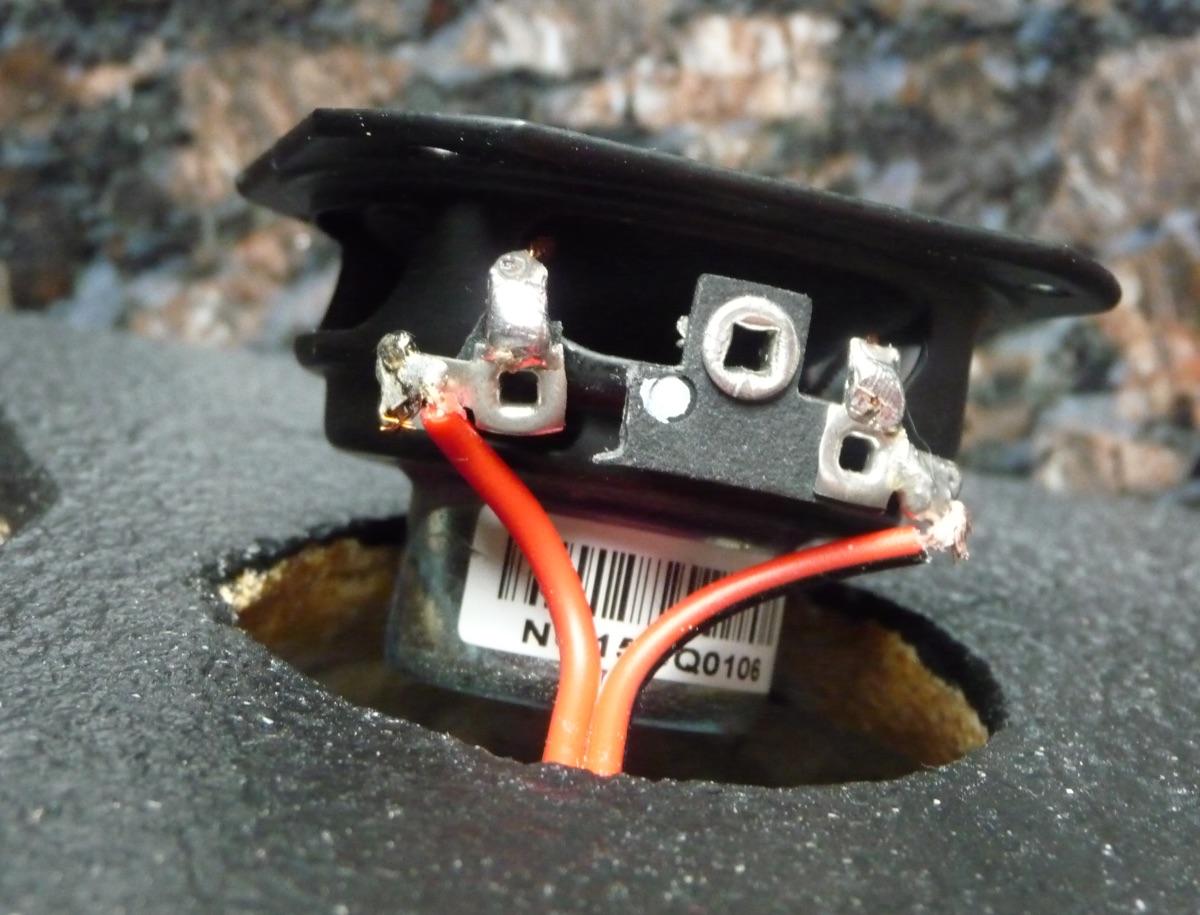

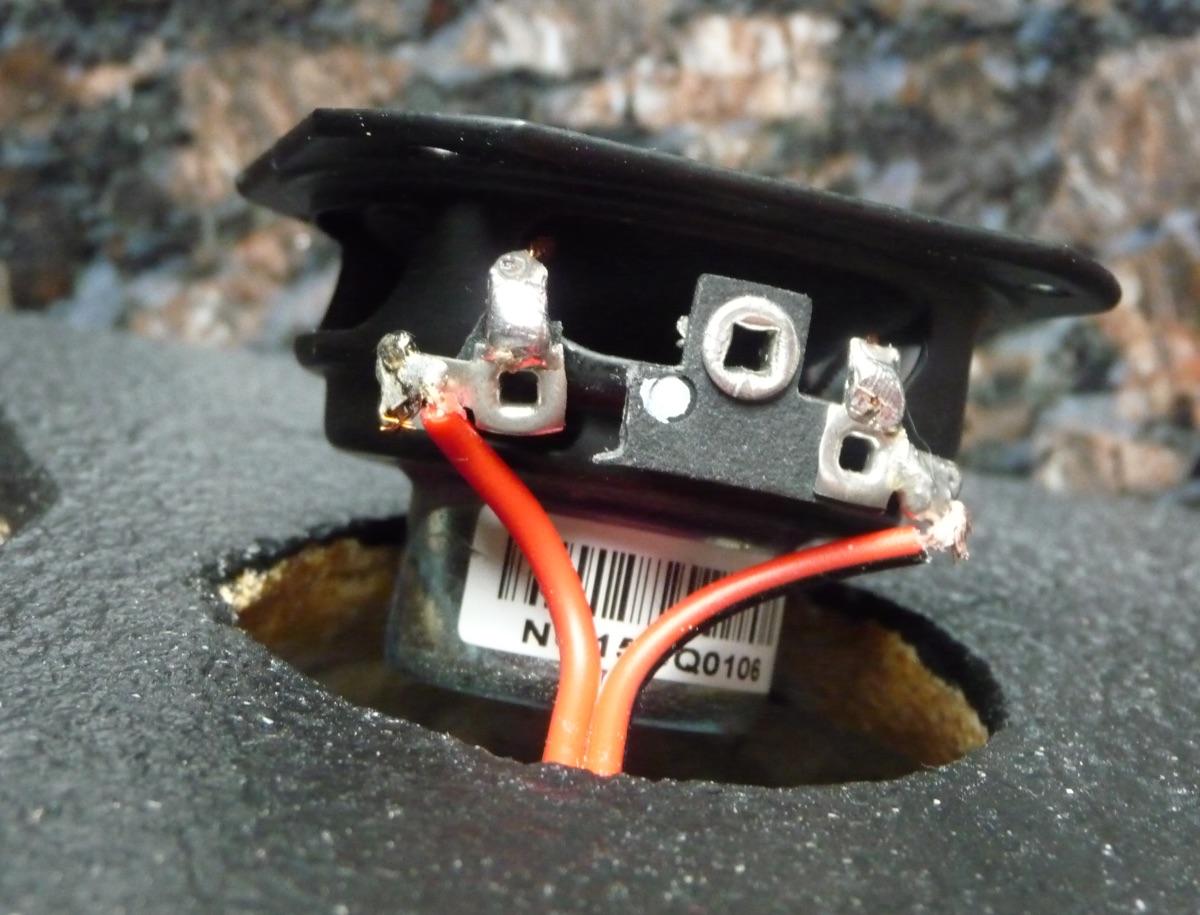

Alright folks, it appears to me that for my own mental health the next step should be to airmail these to the nearest open dumpster and take up yoga. Aside from the nasty solder work, does anyone see another alternative for this busted TC6?

Comments

Then you calm and carry on lol.

For the other fix, I may just add one of these to my next Amazon order: https://www.amazon.com/gp/product/B004UBUV5O/ref=ox_sc_act_title_1?ie=UTF8&psc=1&smid=A3GD9ULQOPYTNA

I have already replaced the too stiff wire leads with a more flexible lighter gauge and opened up the thru-hole.

This may work out okay yet. Action should happen this weekend.

Okay, now back to those cursed TC6's...

Neither of these pictures really do them justice. The cabinets are some of my best work, although the duratex looks a little shabby in the photos. Just like I thought when I heard Kenny's originals, these are a bargain bonanza. I sure wish I'd gotten to hear the new bitty with the tweeter upgrade.

http://techtalk.parts-express.com/forum/speaker-project-gallery/68175-the-itty-bitty-3-way

My assessment is that it is worth the investment to move up to the mini-8. For a few bucks the 6 is fine in this design.

For the Target boxes, I'm not certain whether I'll use the opening in the UP or FORWARD position. Either way I'll probably use a complimentary monotone hardwood. I won't try to replicate the existing look. I'm not that good.

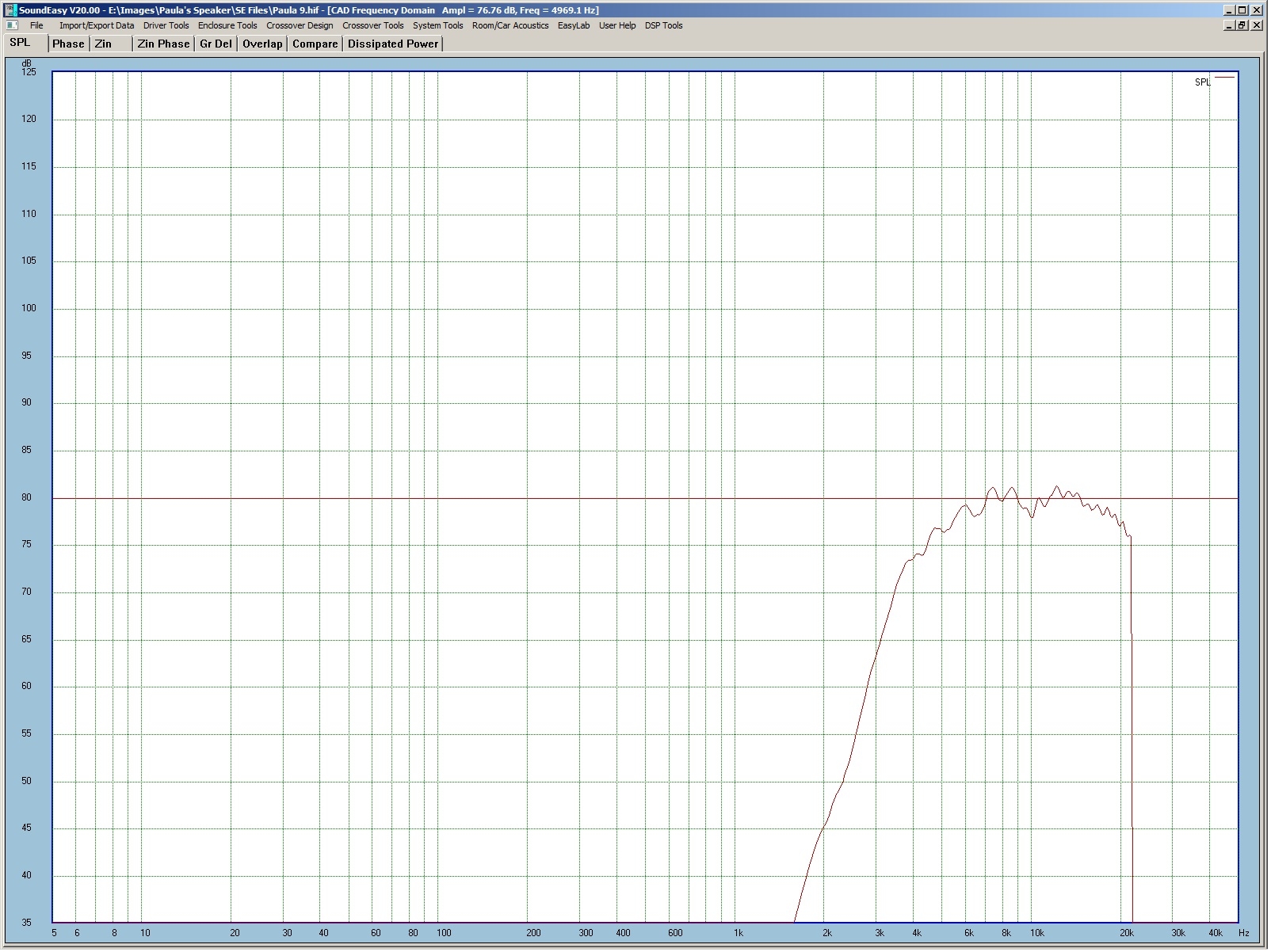

Frequency Response

Tweeter Crossover Sim

Crossover

Ron